From forest to market: the journey of Quebec maple syrup

Every spring, nature reveals a true treasure born of ancestral know-how passed down from generation to generation: maple syrup. Today, modern maple syrup production seeks to combine respect for tradition with environmental concerns. Many producers are adopting sustainable practices, such as responsible forest management, the use of energy-efficient equipment, and waste reduction. These innovations not only preserve the quality and authenticity of the product, but also ensure that this precious heritage can be passed on to future generations. We met with one of our maple syrup families, Érablière René Lussier, to learn more about the behind-the-scenes processes of this production.

1. Maple Tree Tapping

As soon as temperatures fluctuate between nighttime freezing and daytime thawing, generally between February and April, maple syrup producers pierce the maple trees and insert spouts. The rise in sap, triggered by these temperature variations, allows them to harvest maple sap, which contains approximately 2% sugar (a percentage that varies across Quebec).

In modern systems, these spouts are connected to networks of tubing—the famous blue lines seen in maple groves—that allow the sap to flow from the trees to centralized reservoirs. However, a significant amount of manual labor must be done each year beforehand. On high-production land (11,000 taps on the Lussier family's land!), this work begins as early as January, and sometimes even as early as November.

Producers must assess each tree to determine if it can be part of the annual production, noting its circumference and studying its crown. They must also ensure that the lines are not damaged by fallen trees or animals. Some even begin to make shallow taps, which they will return to "tap" once the weather is milder, to avoid damaging the tree.

2. Separating the Water from the Sap

Before evaporation, maple sap undergoes a concentration process to remove some of its water. Reverse osmosis machines are used to filter the water from the sap, retaining sugars and other dissolved solids, thus concentrating the sap and reducing the volume of water to be evaporated; making the process faster and more energy-efficient. The separated water is usually stored and reused in environmentally friendly ways, for example, for irrigation or cleaning machinery.

3. Evaporation

Once concentrated, the maple sap is heated in an evaporator. This process further removes water and concentrates the natural sugars, creating the famous syrup. Traditionally, maple sap evaporation was done in wood-fired metal boilers: a slow process, requiring a lot of fuel, and requiring less precise temperature control. This production process was less efficient and more energy-intensive, producing small quantities of syrup after long hours of work.

Today, evaporation is much faster and more efficient thanks to modern evaporators and the separation step, which allow more sap to be processed in less time. By using less energy and maximizing heat utilization, these modern methods are more environmentally friendly and economical. Daily yield is improved, and the syrup produced is of higher quality, with a more uniform flavor and better shelf life.

4. Filtering and Grading: A Color That Changes with the Season

The evolution of maple syrup throughout the season is influenced by sunlight and biological changes in the maple tree. As the season progresses, the temperature rises and the sap changes, influencing the color and taste of the syrup.

- Golden Syrup: Produced with sap harvested at the very beginning of the maple syrup season, it is distinguished by its light golden color and sweet, delicate flavor.

- Amber Syrup: With its amber color and pure, rich flavor, it is ideal for vinaigrettes or pancakes.

- Dark Syrup: Its more pronounced, caramelized flavor makes it perfect for baking and sauces.

- Very Dark Syrup: Made from sap harvested at the end of the season, this syrup has a full-bodied, powerful flavor.

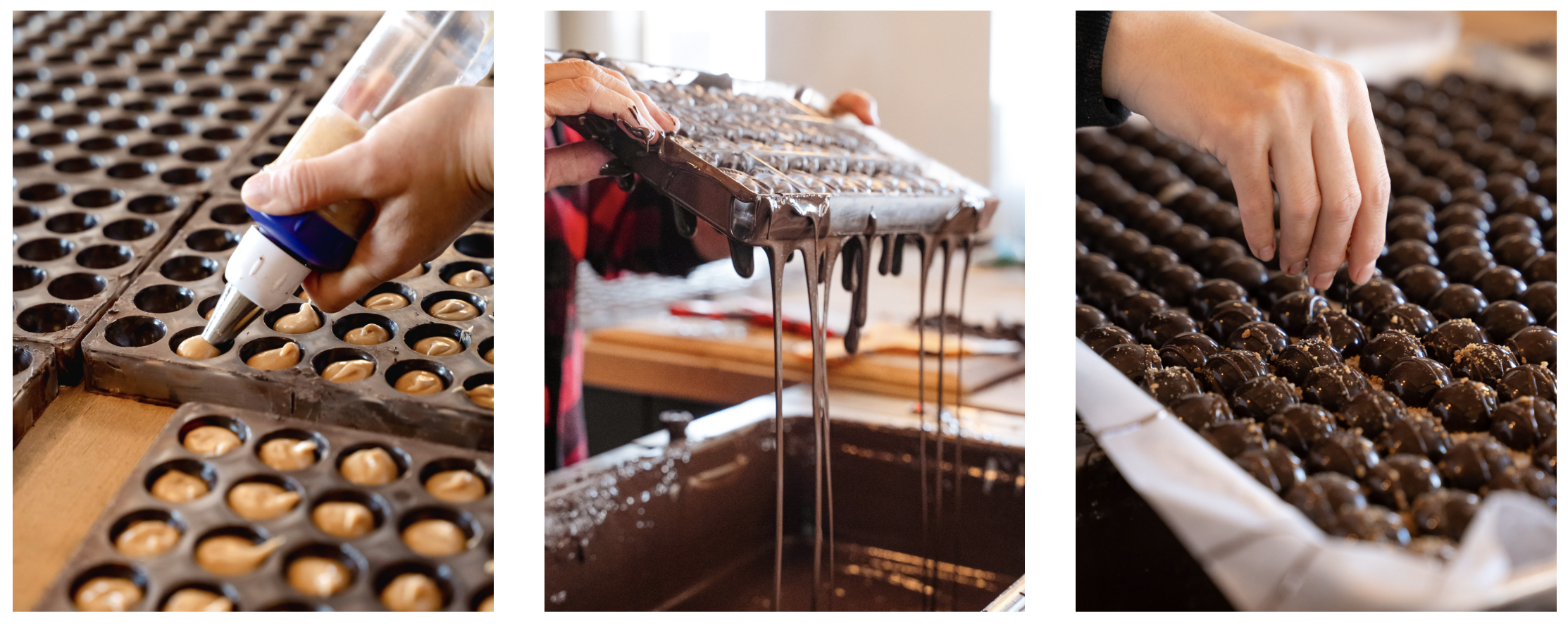

5. Processing and Arrival at Public Markets

After canning and preparing the processed products, maple syrup makes its way to public markets, where local producers offer it to lovers of authentic flavors. Did you know that most of them travel daily to bring you the freshest products possible? Whether in cans, pies, chocolates, doughnuts, or maple butter, this nectar can be enjoyed in a thousand ways!

Visit the Montreal Public Markets to discover the fruits of the maple producers' labors and savor maple syrup in all its richness!